Industry news|2022-06-10| admin

Common methods for gear tooth profile dressing

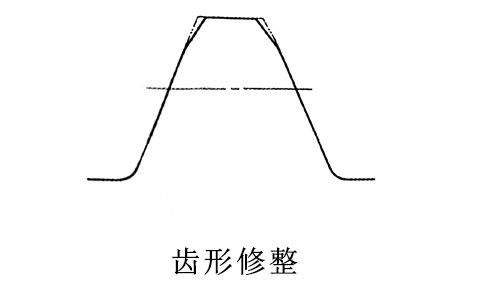

1. Tooth trimming

Tooth trimming is a general term for edge trimming and root trimming. Generally speaking, the method of cultivating relationship is more common. Overhauling refers to consciously trimming the tooth shape of the tooth tip, so that the tooth shape deviates from the correct involute tooth shape.

Therefore, when the gear tooth surface is deformed by an external force, interference with the gear meshed with it can be avoided, noise can be reduced, and the life of the gear can be prolonged. But be careful not to overdress. Excessive trimming is equivalent to increasing the tooth profile error, which will affect the meshing between the rack and pinion.

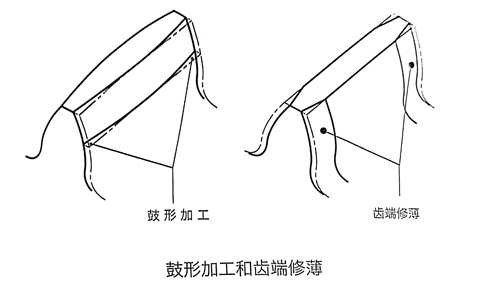

2. Drum processing and tooth end thinning

Drumming and tooth end trimming are trimming along the direction of the tooth line. In particular, the drum shape processing is processing for the purpose of concentrating the contact of the gear teeth to the center of the tooth width. Therefore, the drum shape is appropriately processed in the direction of the tooth line. At this time, care should be taken not to process too much. Excessive drumming will cause a reduction in the contact area of the gear teeth and adversely affect the strength of the gear.

Tooth end thinning is a method of adding appropriate chamfering to both ends of the tooth width.

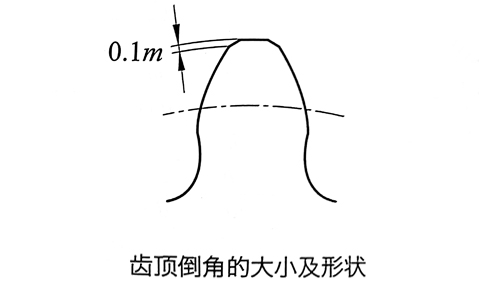

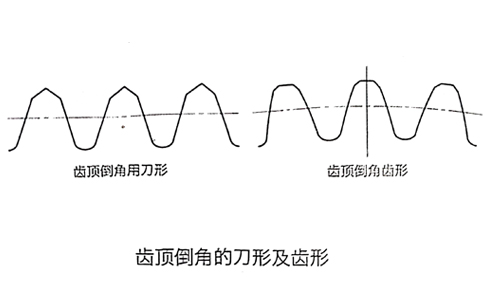

3. Outer diameter machining and tooth tip chamfering

Using the gear hobbing method to process gears, the outer diameter machining of the gear and the tooth tip chamfering can be performed at the same time as the hobbing process. Rack tooling is used for tooth formation processing and outer processing, which can effectively reduce the deviation of the outer diameter and prevent burrs from the tooth tip. Tooth top chamfering has a good effect on preventing collision marks and burrs occurring on the tooth top.

The tooth tip chamfering is implemented, the effective tooth tip height during meshing is reduced, and the meshing ratio is also reduced, so excessive chamfering is usually not performed.

Outer diameter machining and addendum chamfering are sometimes used together, and sometimes one of them is used alone.